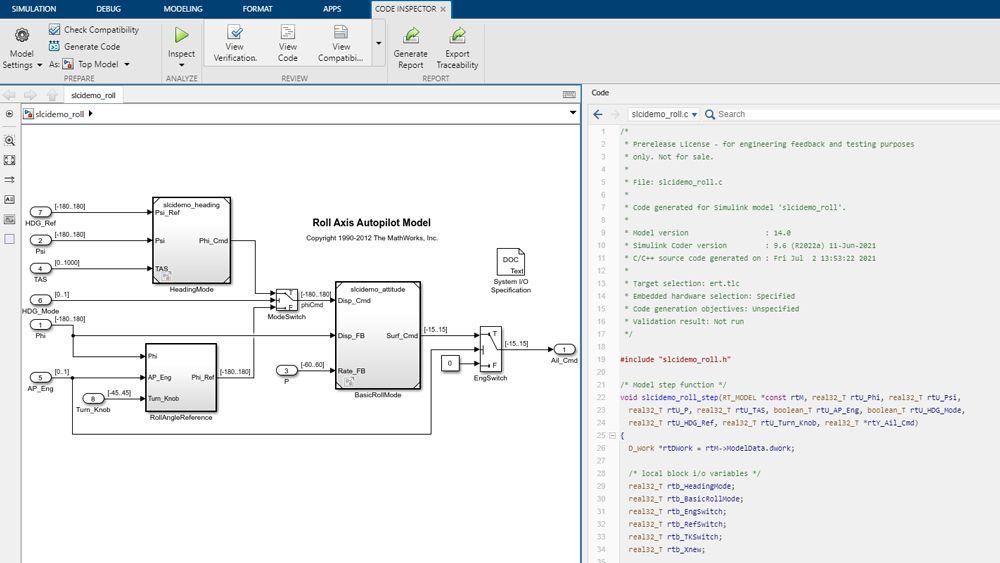

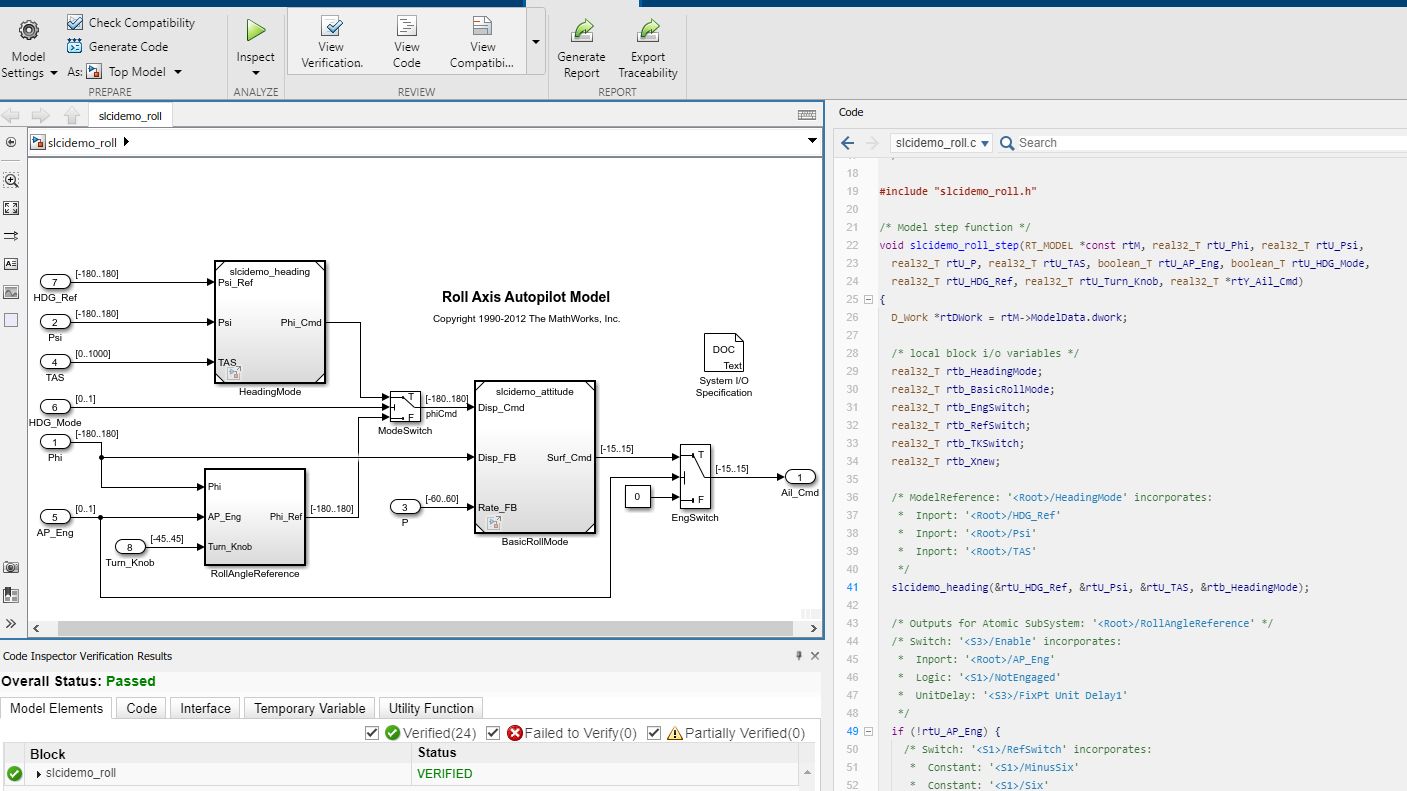

Simulink Code Inspector compara automáticamente el código generado con su modelo de origen para cumplir los objetivos de revisión de código de DO-178 y otros estándares de alta integridad. El inspector de código examina sistemáticamente los bloques, los diagramas de estado, los parámetros y las configuraciones de un modelo para determinar si son funcionalmente equivalentes a las operaciones, los operadores y los datos del código generado.

Simulink Code Inspector ofrece prestaciones de análisis de trazabilidad detallados de modelo a código y de código a modelo. El producto genera informes de equivalencia estructural y trazabilidad que se pueden enviar a las autoridades certificadoras para cumplir los objetivos de DO-178 para la verificación de código de software. Además, incluye una app que permite comprobar la compatibilidad del modelo e inspeccionar el código. Los resultados de la inspección de código aparecen en el modelo y en el código correspondiente.

DO Qualification Kit (for DO-178) proporciona soporte para los estándares de la industria.

Preparación de modelos para generar e inspeccionar código

Prepare los modelos para utilizarlos con Simulink Code Inspector realizando las correspondientes comprobaciones de compatibilidad. Los resultados aparecen directamente en la app Simulink Code Inspector, donde se pueden aplicar las correcciones.

Generación de código a partir de modelos

Genere código a partir de modelos con Embedded Coder.

Inspección de código y revisión de los resultados de la inspección

Inspeccione el código generado para comprobar la conformidad con el modelo. Los resultados aparecen directamente en la app.

Generación de informes y matrices de trazabilidad

Utilice la app para generar informes de inspección y trazabilidad de código.

Recursos del producto:

“Con el diseño basado en modelos, nuestro primer vuelo fue perfecto; no tuvimos problemas de control ni de integración. Con Embedded Coder y la generación de código de normas de control a partir de nuestro modelo de Simulink, pudimos eliminar todos los retrasos causados por la generación manual de código, lo que liberó al equipo para trabajar en los objetivos generales del programa”.

Mike Bothwell, Bell Helicopter

¿Tiene interés en Simulink Code Inspector?

¿Tiene preguntas?

Comuníquese con el equipo técnico experto en Simulink Code Inspector.