CDSP Peripheral Configuration

Description

Use the Hardware Mapping tool to view and edit the CDSP peripheral configuration parameters in Infineon® AURIX™ TC4x model.

Using the Hardware Mapping tool, you can:

View and edit configuration parameters for CDSP block.

Check for any conflicts between the peripherals.

Open the CDSP Peripheral Configuration

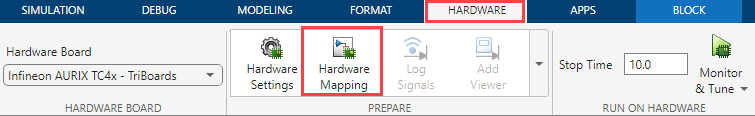

In the Hardware tab of the Simulink® model, click Model Settings to open the Configuration Parameters dialog box. Click on Hardware Implementation in the left pane and set Hardware board parameter to

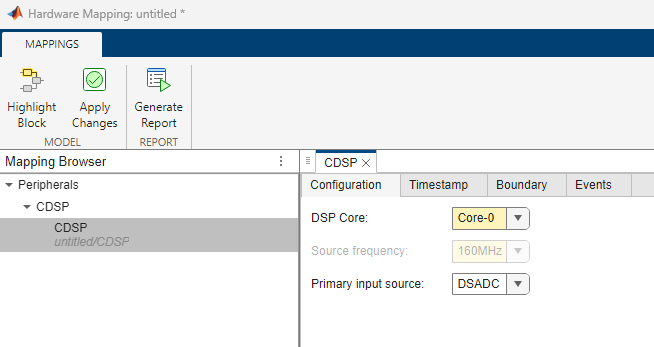

Infineon AURIX TC4x - TriBoards.In the Hardware tab of the Simulink model, click Hardware Mapping. In the Mapping Browser pane, navigate to Peripherals > CDSP and select the tab for the peripheral parameters that you want to view and edit.

Parameters

Configuration

Select the primary input source of data on which the CDSP block performs different signal processing techniques.

This parameter must match the block or GP input registers connected to the Primary input port of the CDSP block in the Simulink model.

Note

If you set the DSP Filter chain parameter to

Demo FIR (FC0),Advanced average 1 (FC1),Advanced median (FC3), orAdvanced average 2 (FC4), then the CDSP block expects a 16-bit primary input from the GP registers.If you set the DSP Filter chain parameter to

Basic data accumulation (FC2)orBasic AURIX (FCM), then the CDSP block expects a 32-bit primary input from the GP registers, where the upper 16 bits represent side band signals of the data accumulation (DA) filter block. These side band signals control the integration operation in the DA filter block, with 0x6000 for integrator start and reset and 0x4000 for integrator start.

Select the TMADC channel number from which the CDSP block receives primary input data.

Note

This parameter must match the read-only parameter Channel in the Channel N tab of the corresponding TMADC block in the Hardware Mapping tool.

Dependencies

To enable this parameter, set the Primary input source

parameter to TMADC.

Select the secondary input source of data for Math filter block.

This parameter must match with the block or GP register connected to the Secondary input port of the CDSP block in the Simulink model.

Note

If you set the DSP Filter chain parameter to

Demo FIR (FC0),Advanced average 1 (FC1),Advanced median (FC3), orAdvanced average 2 (FC4), then the CDSP block expects a 16-bit secondary input from the GP registers.If you set the DSP Filter chain parameter to

Basic data accumulation (FC2)orBasic AURIX (FCM), then the CDSP block expects a 32-bit secondary input from the GP registers, where the first 16 bits represent side band signals of the data accumulation (DA) filter block. These side band signals control the integration operation in DA filter block, with 0x6000 for integrator start and reset and 0x4000 for integrator start.

Dependencies

To enable this parameter, set the DSP Filter chain

block parameter to Advanced average 1 (FC1),

Basic data accumulation (FC2), or

Advanced average 2 (FC4). This choice adds a

Math tab in the CDSP block, where you must set the Math

operation parameter to Addition with CDSP secondary

input or subtraction with CDSP secondary

input.

Select the TMADC channel number from which the CDSP block receives secondary input data.

Note

This parameter must match the read-only parameter Channel in the Channel # tab of the corresponding TMADC block in the Hardware mapping tool.

Dependencies

To enable this parameter, set the Secondary input

source parameter to TMADC.

Timestamp

Specify the division factor for the clock frequency to use in analog-to-digital conversion (ADC).

Dependencies

To enable this parameter, select the Enable timestamp output parameter in the CDSP block in the Simulink model.

Specify the source of the gate signal to trigger the timestamp.

Note

You must configure the appropriate trigger from the PWM block with a rate

(1/initial clock frequency of PWM) that is greater than the conversion time

of the filtered data output. Calculate this conversion time as Size

of filtered data x clock cycles / FADC.

For the filter chain FC0 with analog to digital

conversion frequency (FADC) of 160

MHz, 128 filter taps, and a decimation rate of

1, it requires 249 clock cycles to

output correct filtered data.

Dependencies

To enable this parameter, select the Enable timestamp parameter in the CDSP block of the Simulink model.

Specify the hardware trigger for the timestamp.

Dependencies

To enable this parameter, select the Enable timestamp parameter in the CDSP block of the Simulink model.

Select the type of hardware trigger edge to trigger the timestamp.

Dependencies

To enable this parameter, select the Enable timestamp parameter in the CDSP block of the Simulink model.

Specify the gate trigger delay for the timestamp.

Dependencies

To enable this parameter, select the Enable timestamp parameter in the CDSP block of the Simulink model.

Boundary

Set the lower limit of the boundary band to check the result.

Set the upper limit of the boundary band to check the result.

Enable hysteresis to avoid metastable states and switching due to internal ground bounce.

Activate boundary flag based on the boundary band limits.

Dependencies

To enable this parameter, disable the Enable hysteresis on boundary flag parameter.

Service request based on the boundary mode.

Integrator Control

Specify the hardware trigger source for integration in the DA filter block.

Dependencies

To enable this parameter, set the DSP filter chain

parameter to Basic data accumulation (FC2) or

Basic AURIX (FCM) in the CDSP block of the

Simulink model.

Specify the hardware trigger for integration in the DA filter block.

Note

Configure the ADC trigger from the PWM block. The Module, Timer submodule, Timer unit, and Trigger Channel parameter values in PWM Peripheral Configuration must match the values of the Window gate source and Hardware trigger parameters.

If your application model uses two CDSP blocks with DSP filter chain parameter set to

Basic data accumulation (FC2)andBasic AURIX (FCM), ensure sufficient time interval between subsequent PWM triggers signals for both filters chains to complete their operations. Otherwise, the filter chain produces a zero output for the next trigger signal.

Dependencies

To enable this parameter, set the DSP filter chain

parameter to Basic data accumulation (FC2) or

Basic AURIX (FCM) in the CDSP block of the

Simulink model.

Specify the hardware trigger edge for integration in the DA filter block.

Dependencies

To enable this parameter, set the DSP filter chain

parameter to Basic data accumulation (FC2) or

Basic AURIX (FCM) in the CDSP block of the

Simulink model.

Specify the trigger delay for integration in the DA filter block.

Dependencies

To enable this parameter, set the DSP filter chain

parameter to Basic data accumulation (FC2) or

Basic AURIX (FCM) in the CDSP block of the

Simulink model.

Events > Result Interrupt

Select this parameter to enable a result interrupt.

Specify the interrupt condition for the filtered result.

Source of the gate signal to trigger the filtered result.

Note

Ensure that you have configured the appropriate trigger using the PWM block.

Specify the hardware trigger for the filtered result.

Specify the trigger delay for the filtered result.

Events > Timestamp

Select this parameter to enable the timestamp interrupt.

Dependencies

To enable this parameter, select the Enable timestamp parameter in the CDSP block of the Simulink model.

Version History

Introduced in R2024a

See Also

MATLAB Command

You clicked a link that corresponds to this MATLAB command:

Run the command by entering it in the MATLAB Command Window. Web browsers do not support MATLAB commands.

Seleccione un país/idioma

Seleccione un país/idioma para obtener contenido traducido, si está disponible, y ver eventos y ofertas de productos y servicios locales. Según su ubicación geográfica, recomendamos que seleccione: .

También puede seleccionar uno de estos países/idiomas:

Cómo obtener el mejor rendimiento

Seleccione China (en idioma chino o inglés) para obtener el mejor rendimiento. Los sitios web de otros países no están optimizados para ser accedidos desde su ubicación geográfica.

América

- América Latina (Español)

- Canada (English)

- United States (English)

Europa

- Belgium (English)

- Denmark (English)

- Deutschland (Deutsch)

- España (Español)

- Finland (English)

- France (Français)

- Ireland (English)

- Italia (Italiano)

- Luxembourg (English)

- Netherlands (English)

- Norway (English)

- Österreich (Deutsch)

- Portugal (English)

- Sweden (English)

- Switzerland

- United Kingdom (English)