Gate Valve (IL)

Gate valve in an isothermal liquid system

Libraries:

Simscape /

Fluids /

Isothermal Liquid /

Valves & Orifices /

Flow Control Valves

Description

The Gate Valve (IL) block represents flow control by a gate valve in an isothermal liquid network. The valve comprises a round, sharp-edged orifice and a round gate with the same diameter. The gate opens or closes according to the displacement signal at port S. A positive signal retracts the gate and opens the valve.

Opening Area

Gate Valve Opening Schematic

The area open to flow as the gate retracts is:

where d0 is the Valve orifice diameter. The area shielded by the gate in a partially open valve is:

where Δl is the gate displacement, which is the sum of the signal at port S and the Gate position when fully covering orifice.

If displacement exceeds the Orifice diameter, the valve area Aopen is the sum of the maximum orifice area and the Leakage area:

For any combination of the signal at port S and the gate offset that is less than 0, the minimum valve area is the Leakage area.

Numerically Smoothed Displacement

When the valve is in a near-open or near-closed position,

you can maintain numerical robustness in your simulation by adjusting the

Smoothing factor parameter. If the Smoothing

factor parameter is nonzero, the block smoothly saturates the gate

displacement between 0 and the Valve orifice

diameter parameter. For more information, see Numerical Smoothing.

Mass Flow Rate Equation

Mass is conserved through the valve:

The mass flow rate through the valve is calculated as:

where:

Cd is the Discharge coefficient.

Avalve is the valve open area.

Aport is the Cross-sectional area at ports A and B.

is the average fluid density.

Δp is the valve pressure difference pA – pB.

The critical pressure difference, Δpcrit, is the pressure differential associated with the Critical Reynolds number, Recrit, which is the flow regime transition point between laminar and turbulent flow:

Pressure loss describes the reduction of pressure in the valve due to a decrease in area. PRloss is calculated as:

Pressure recovery describes the positive pressure change in the valve due to an increase in area. If you do not want to capture this increase in pressure, clear the Pressure recovery check box. In this case, PRloss is 1.

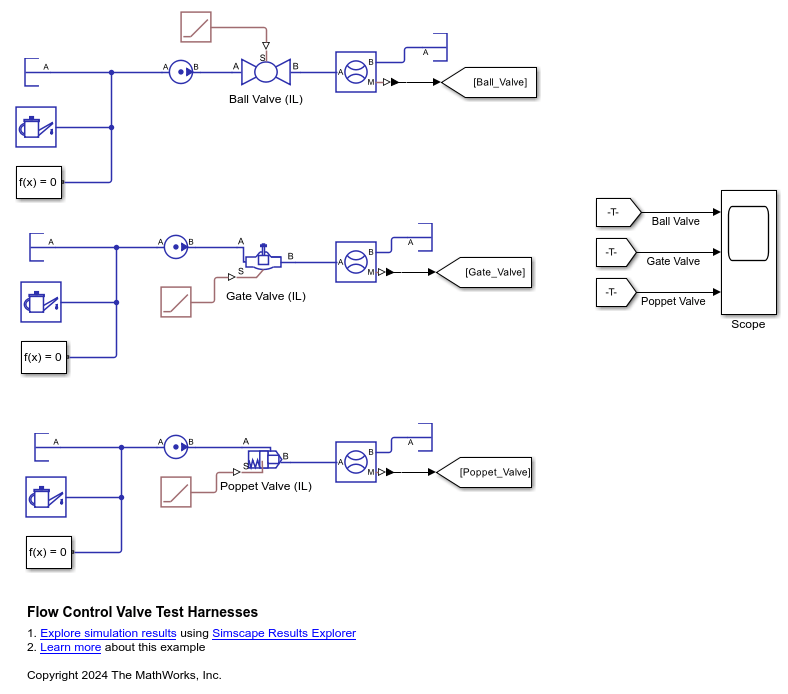

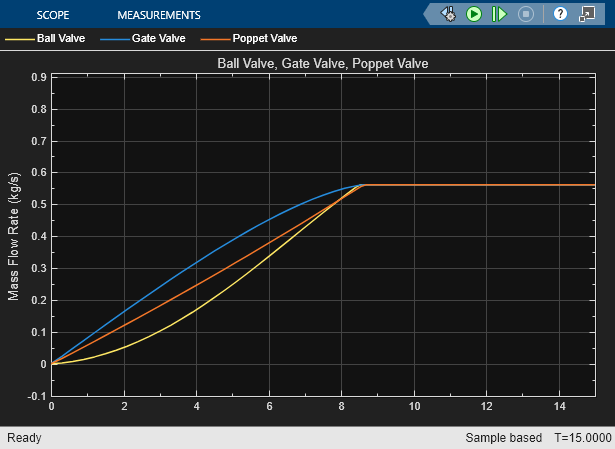

Examples

Ports

Input

Conserving

Parameters

Extended Capabilities

Version History

Introduced in R2020a