Heat Exchanger (TL-MA)

Models heat exchange between a moist air network and a thermal liquid network

Libraries:

Simscape /

Fluids /

Heat Exchangers /

Thermal Liquid - Moist Air

Description

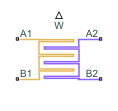

The Heat Exchanger (TL-MA) block models a heat exchanger with one moist air network, which flows between ports A2 and B2, and one thermal liquid network, which flows between ports A1 and B1. The fluid streams can be aligned in parallel, counter, or cross-flow configurations.

A thermal liquid-moist air heat exchanger is not appropriate for refrigeration cooling systems. See Condenser Evaporator (2P-MA) or Condenser Evaporator (TL-2P) for heat exchangers that can be employed in refrigeration applications.

You can model the moist air side as flow within tubes, flow around thermal liquid tubing, or by an empirical, generic parameterization. The moist air side comprises air, trace gas, and water vapor that may condense throughout the heat exchange cycle. The block model accounts for the latent heat that is released when water condenses on the heat transfer surface. This liquid layer does not collect on the surface and is assumed to be completely removed from the downstream moist air flow. The humidity condensation rate is returned as a physical signal at port W.

The block uses the Effectiveness-NTU (E-NTU) method to model heat transfer through the shared wall. Fouling on the exchanger walls, which increases thermal resistance and reduces the heat exchange between the two fluids, is also modeled. You can also optionally model fins on both the moist air and thermal liquid sides. Pressure loss due to viscous friction on both sides of the exchanger can be modeled analytically or by generic parameterization, which you can use to tune to your own data.

You can model the thermal liquid side as flow within tubes, flow around moist air tubing, or by an empirical, generic parameterization.

Heat Exchanger Configuration

The heat exchanger effectiveness is based on the selected heat exchanger configuration, the fluid properties, the tube geometry and flow configuration on each side of the exchanger, and the usage and size of fins.

The Flow arrangement parameter assigns the relative flow paths between the two sides:

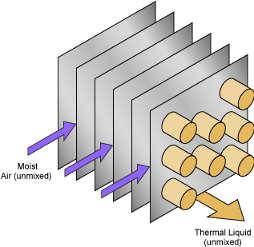

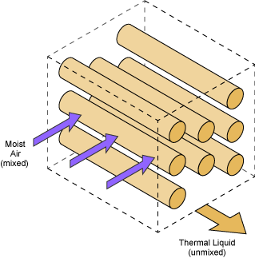

Parallel flowindicates the fluids are moving in the same direction.Counter flowindicates the fluids are moving in parallel, but opposite directions.Cross flowindicates the fluids are moving perpendicular to each other.

When Flow arrangement is set to Cross

flow, use the Cross flow arrangement

parameter to indicate whether the thermal liquid or moist air flows are

separated into multiple paths by baffles or walls. Without these separations,

the flow can mix freely and is considered mixed. Both

fluids, one fluid, or neither fluid can be mixed in the cross-flow arrangement.

Mixing homogenizes the fluid temperature along the direction of flow of the

second fluid, and varies perpendicular to the second fluid flow.

Unmixed flows vary in temperature both along and perpendicular to the flow path of the second fluid.

Sample Cross-Flow Configurations

Note that the flow direction during simulation does not impact the selected flow arrangement setting. The ports on the block do not reflect the physical positions of the ports in the physical heat exchange system.

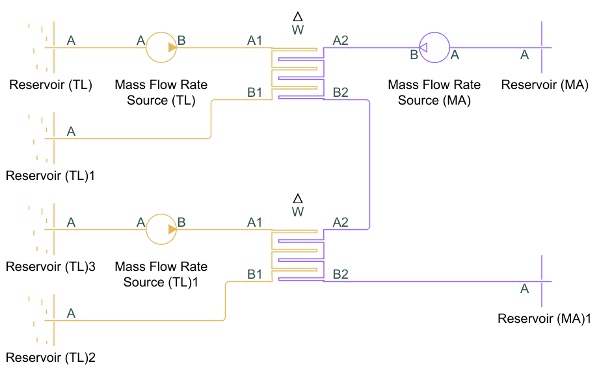

All flow arrangements are single-pass, which means that the fluids do not make multiple turns in the exchanger for additional points of heat transfer. To model a multi-pass heat exchanger, you can arrange multiple Heat Exchanger (TL-MA) blocks in series or in parallel.

For example, to achieve a two-pass configuration on the moist air side and a single-pass configuration on the thermal liquid side, you can connect the moist air sides in series and the thermal liquid sides to the same input in parallel (such as two Mass Flow Rate Source blocks with half of the total mass flow rate), as shown below.

The Flow geometry parameter sets the flow arrangement of the fluid of the respective dialog tab as either inside a tube or set of tubes, or perpendicular to a tube bank. You can also specify an empirical, generic configuration.

When Flow geometry is set to Flow

perpendicular to bank of circular tubes, use the

Tube bank grid arrangement parameter to define the tube

bank alignment of the other fluid as either Inline or

Staggered. The red, downward-pointing arrow in

the figure below indicates the direction of the fluid flowing external to the

tube bank. The Inline figure also shows the Number of tube rows along

flow direction and the Number of tube segments in each

tube row parameters. Here, flow direction

refers to the fluid of the respective dialog tab, and tube

refers to the tubing of the other fluid. The Length of each tube

segment in a tube row parameter is indicated in the Staggered

figure.

Only one fluid can have Flow geometry set to

Flow perpendicular to bank of circular tubes at a

time. The other fluid must be configured to either Flow inside one

or more tubes or Generic. If

Flow geometry for both fluids is set to

Flow perpendicular to bank of circular tubes, you

will receive an error.

The heat exchanger configuration does not have fins when the Total

fin surface area parameter is 0 m^2. Fins

introduce additional surface area for heat transfer. Each fluid side has a

separate fin area and parameters that describe the fins in that fluid. For

example, when the thermal liquid flows inside the tubes and the moist air flows

outside of the tubes, the Total fin surface area and

Fin efficiency parameters in the Thermal

Liquid 1 section describe the fins protruding into the tube. The

Total fin surface area and Fin

efficiency parameters in the Moist Air 2

section describe the fins outside of the tubes.

Effectiveness-NTU Heat Transfer

The heat transfer rate is calculated over the averaged properties of both fluids.

The convective heat transfer is

where:

CMin is the lesser of the heat capacity rates of the two fluids. The heat capacity rate is the product of the fluid specific heat, cp, and the fluid mass flow rate. CMin is always positive.

TIn,TL is the inlet temperature of the thermal liquid.

TIn,MA is the inlet temperature of the moist air.

ε is the heat exchanger effectiveness.

Effectiveness is a function of the heat capacity rate and the number of transfer units, NTU, and also varies based on the heat exchanger flow arrangement, which is discussed in more detail in Effectiveness by Flow Arrangement. The NTU is calculated as:

where R is the total thermal resistance between the two flows, due to convection, conduction, and any fouling on the tube walls:

and where:

U is the convective heat transfer coefficient of the respective fluid. This coefficient is discussed in more detail in Heat Transfer Coefficients.

F is the Fouling factor on the thermal liquid or moist air side, respectively.

RW is the Thermal resistance through heat transfer surface.

ATh is the heat transfer surface area of the respective side of the exchanger. ATh is the sum of the wall surface area, AW, and the Total fin surface area, AF:

where ηF is the Fin efficiency.

The fluid properties that the block uses in heat transfer calculations are the average between the value at the inlet and the value in the fluid volume.

The heat exchanger effectiveness varies according to its flow configuration and the mixing in each fluid.

When Flow arrangement is set to

Parallel flow:When Flow arrangement is set to

Counter flow:When Flow arrangement is set to

Cross flowand Cross flow arrangement is set toBoth fluids unmixed:When Flow arrangement is set to

Cross flowand Cross flow arrangement is set toBoth fluids mixed:

When one fluid is mixed and the other unmixed, the equation for

effectiveness depends on the relative heat capacity rates of the fluids.

When Flow arrangement is set to Cross

flow and Cross flow arrangement

is set to either Thermal Liquid 1 mixed & Moist Air 2

unmixed or Thermal Liquid 1 unmixed &

Moist Air 2 mixed:

When the fluid with Cmax is mixed and the fluid with Cmin is unmixed:

When the fluid with Cmin is mixed and the fluid with Cmax is unmixed:

CR denotes the ratio between the heat capacity rates of the two fluids:

Conductive Heat Transfer

The conductive heat transfer in a zone is

where:

Tout,TL is the zone outlet temperature of the thermal liquid.

Tout,MA is the zone outlet temperature of the moist air.

Rcond is the total conductive thermal resistance between the two flows,

where:

AW is the wall surface area.

k is the thermal conductivity of each fluid.

DH is the hydraulic diameter.

The total heat transfer is the sum of the convective and conductive heat transfer. The conductive heat transfer is negligible compared to the convective heat transfer. When the flow rate is zero, the convective heat transfer is also zero. However, because heat transfer from convection and conduction operate independently of each other, there is still conductive heat transfer even when the convective heat transfer is zero.

Condensation

On the moist air side, a layer of condensation may form on the heat transfer surface. This liquid layer can influence the amount of heat transferred between the moist air and thermal liquid. The equations for E-NTU heat transfer above are given for dry heat transfer. To correct for the influence of condensation, the E-NTU equations are additionally calculated with the wet parameters listed below. Whichever of the two calculated heat flow rates results in a larger amount of moist air side cooling is used in heat calculations [1] [2]. To use this method, the Lewis number is assumed to be close to 1, which is true for moist air [1][2].

E-NTU Quantities Used for Heat Transfer Rate Calculations

| Dry calculation | Wet calculation | |

|---|---|---|

| Moist air zone inlet temperature | Tin,MA | Tin,wb,MA |

| Heat capacity rate | ||

| Heat transfer coefficient | UMA |

where:

Tin,MA is the moist air inlet temperature.

Tin,wb,MA is the moist air wet-bulb temperature associated with Tin,MA.

is the dry air mass flow rate.

is the moist air heat capacity per unit mass of dry air.

is the equivalent heat capacity. The equivalent heat capacity is the change in the moist air specific enthalpy (per unit of dry air), , with respect to temperature at saturated moist air conditions:

The mass flow rate of the condensed water vapor leaving the moist air mass flow depends on the relative humidity between the moist air inlet and the channel wall and the heat exchanger NTUs:

where:

Wwall,MA is the humidity ratio at the heat transfer surface.

Win,MA is the humidity ratio at the moist air flow inlet.

NTUMA is the number of transfer units on the moist air side, calculated as:

The energy flow associated with water vapor condensation is based on the difference between the vapor specific enthalpy, hwater, wall, and the specific enthalpy of vaporization, hfg, for water:

The condensate is assumed to not accumulate on the heat transfer surface, and does not influence geometric parameters such as tube diameter.

Heat Transfer Coefficients

The equations below apply to both the thermal liquid and moist air sides and use the respective fluid properties.

The convective heat transfer coefficient varies according to the fluid Nusselt number:

where:

Nu is the mean Nusselt number, which depends on the flow regime.

k is the fluid thermal conductivity.

DH is tube hydraulic diameter.

For turbulent flows, the Nusselt number is calculated with the Gnielinski correlation:

where:

Re is the fluid Reynolds number.

Pr is the fluid Prandtl number.

For laminar flows, the Nusselt number is set by the Laminar flow Nusselt number parameter.

For transitional flows, the Nusselt number is a blend between the laminar and turbulent Nusselt numbers.

When Flow geometry is set to Flow

perpendicular to bank of circular tubes, the Nusselt number is

calculated based on the Hagen number, Hg, and depends on the Tube bank

grid arrangement setting:

where:

D is the Tube outer diameter.

lL is the Longitudinal tube pitch (along flow direction), the distance between the tube centers along the flow direction. Flow direction is the direction of flow of the external fluid.

lT is the Transverse tube pitch (perpendicular to flow direction), the distance between the centers of the tubing in one row of the other fluid.

lD is the diagonal tube spacing, calculated as

For more information on calculating the Hagen number, see [6].

The measurements lL and lT are shown in the tube bank cross-section below. These distances are the same for both grid bank arrangement types.

Cross-section of Tubing with Pitch Measurements

When the Heat transfer coefficient model parameter is set

to Colburn equation or when Flow

geometry is set to Generic, the

Nusselt number is calculated by the empirical the Colburn equation:

where a, b, and c are defined in the Coefficients [a, b, c] for a*Re^b*Pr^c parameter.

Pressure Loss

The equations below apply to both the thermal liquid and moist air sides and use the respective fluid properties.

The pressure loss due to viscous friction varies depending on flow regime and configuration.

For turbulent flows, when the Reynolds number is above the Turbulent

flow lower Reynolds number limit parameter, and when

Pressure loss model is set to Correlations

for flow inside tubes, the pressure loss due to friction is

calculated in terms of the Darcy friction factor.

For the thermal liquid side, the pressure differential between a port A1 and the internal node I1 is:

where:

A1 is the total flow rate through port A1.

fD,A is the Darcy friction factor, according to the Haaland correlation. When the Local resistance specification parameter is

Aggregate equivalent length,where εR is the thermal liquid pipe Internal surface absolute roughness. The friction factor is dependent on the Reynolds number, and the block calculates this value at both ports for each liquid.

L is the Total length of each tube on the thermal liquid side.

LAdd is the thermal liquid side Aggregate equivalent length of local resistances, which is the equivalent length of a tube that introduces the same amount of loss as the sum of the losses due to other local resistances in the tube.

ACS is the total tube cross-sectional area.

The pressure differential between port B1 and internal node I1 is:

where B1 is the total flow rate through port B1.

When the Local resistance specification parameter is

Aggregate equivalent length, the Darcy friction

factor at port B1 is:

When the Local resistance specification parameter is

Local loss coefficient, the Darcy friction

factors at ports A1 and B1 are

where Clocalloss is the value of the Total local loss coefficient parameter.

For laminar flows, when the Reynolds number is below the Laminar

flow upper Reynolds number limit parameter, and when

Pressure loss model is set to Correlations

for flow inside tubes, the block calculates the pressure loss

due to friction in terms of the Laminar friction constant for Darcy

friction factor parameter, λ.

λ is a user-defined parameter when Tube

cross-section is Generic. Otherwise,

the block calculates the value internally.

The pressure differential between port A1 and internal node I1 is:

where μ is the fluid dynamic viscosity. The pressure differential between port B1 and internal node I1 is:

For transitional flows, when Pressure loss model is set

to Correlations for flow inside tubes, the pressure

differential due to viscous friction is a smoothed blend between the values for

laminar and turbulent pressure losses.

When Pressure loss model is set to Pressure

loss coefficient or when Flow geometry is

set to Generic, the pressure losses due to viscous

friction are calculated with an empirical pressure loss coefficient,

ξ. The same equations apply to both the moist air and

thermal liquid sides and use the respective fluid properties.

For the thermal liquid side, the pressure differential between port A1 and internal node I1 is:

The pressure differential between port B1 and internal node I1 is:

When Flow geometry is set to Flow

perpendicular to bank of circular tubes, the Hagen number is

used to calculate the pressure loss due to viscous friction. The same equations

apply to both the moist air and thermal liquid sides and use the respective

fluid properties.

For the moist air side, the pressure differential between port A2 and internal node I2 is:

where:

μ is the moist air fluid dynamic viscosity.

NR is the Number of tube rows along flow direction. When moist air is flowing external to a tube bank, this is the number of thermal liquid tube rows along the direction of the moist air flow.

The pressure differential between port B2 and internal node I2 is:

When the Pressure loss model is set to Euler

number per tube row or when Flow geometry

is set to Generic, the pressure loss due to viscous

friction is calculated with a pressure loss coefficient, in terms of the Euler

number, Eu:

where ξ is the empirical pressure loss coefficient.

The pressure differential between port A2 and internal node I2 is:

The pressure differential between port B2 and internal node I2 is:

Wall Thermal Mass

If you select Enable wall thermal mass, the block models the heat exchanger wall thermal mass, which introduces a delay in the wall's transient response to changes in temperature or heat flux. If you model thermal mass, the wall stores heat in its bounds. This heat storage slows the transition between steady states so that a thermal perturbation on one side does not immediately manifest on the other side. The lag persists until the heat flow rates from the two sides balance.

If you select Enable wall thermal mass, the wall energy conservation is

where:

Mwall is the value of the Wall mass parameter.

cp,wall is the value of the Wall specific heat parameter.

Twall is the effective wall temperature on each side. The block uses this value to model the transient response. You cannot measure this value.

The heat transfer to each fluid is

where:

Tin is the fluid inlet temperature on each side.

C is the heat capacity rate for each fluid.

The number of heat transfer units between the fluid and the wall on each side is

where A is the wall surface area and U is the heat transfer coefficient.

Conservation Equations

The total mass accumulation rate in the thermal liquid is defined as:

where:

MTL is the total mass of the thermal liquid.

A1 is the mass flow rate of the fluid at port A1.

B1 is the mass flow rate of the fluid at port B1.

The flow is positive when flowing into the block through the port.

The energy conservation equation relates the change in specific internal energy to the heat transfer by the fluid

where:

uTL is the thermal liquid specific internal energy.

φA1 is the energy flow rate at port A1.

φB1 is the energy flow rate at port B1.

Q is heat transfer rate, which is positive when leaving the thermal liquid volume.

The block has mass conversion equations for the moist air mixture, water vapor, trace gas, and water droplets.

Note

If the Trace gas model parameter is

None in the Moist Air Properties (MA) block, the moist air

network does not model trace gas. In this case, in the Heat Exchanger (TL-MA)

block, the conservation equation for trace gas is set to 0.

If you clear the Enable entrained water droplets in the Moist Air Properties (MA) block, the moist air network does not model entrained water droplets. In this case, in the Heat Exchanger (TL-MA) block, the conservation equation for water droplets is set to 0.

The accumulation rate for the moist air mixture accounts for the changes of the moist air mass flow through the exchanger ports and the condensation mass flow rate,

where:

A2 is the moist air mass flow rate at port A2.

A2 is the moist air mass flow rate at port B2.

w,cond is the rate of water vapor condensation due to a saturated fluid volume.

w,conv is the rate of condensation on the wall surface.

d,evap is the rate of water droplet evaporation.

The mass conservation equation for water vapor is

where xw is the mass fraction of the vapor, ρMAI is the density of the moist air in the fluid volume, and V is the total moist air volume.

w,net is the net water vapor mass flow rate,

where:

is the water vapor mass flow rate at port A2.

is the water vapor mass flow rate at port B2.

The trace gas mass balance is

where:

xg is the mass fraction of the trace gas.

is the trace gas mass flow rate at port A2.

is the trace gas mass flow rate at port B2.

The water droplet mass balance is

where rdI is the mass ratio of the water droplets to the moist air in the fluid volume.

is the net water droplet mass flow rate,

where:

d,A2 is the water droplets mass flow rate at port A2.

d,A2 is the water droplets mass flow rate at port B2.

λd is the value of the Fraction of condensate entrained as water droplets parameter.

On the moist air side, energy conservation accounts for the change in specific internal energy due to heat transfer and water vapor condensing out of the moist air mass,

where:

ua,I, uw,I, and ug,I are the internal energies of the air, water vapor, and gas, respectively.

cpI is the moist air specific heat.

cpdI is the water droplet specific heat.

rd is the mass ratio of water droplets to moist air.

pI is the pressure of the internal volume.

TI is the temperature of the internal volume.

RI is the internal volume specific gas constant.

hdI is the water droplet specific enthalpy in the fluid volume.

hdH is the water droplet specific enthalpy on the wall surface.

ϕA2 is the energy flow rate at port A2.

ϕB2 is the energy flow rate at port B2.

The heat transferred to or from the moist air, Q, is equal to the heat transferred from or to the thermal liquid.

Examples

Ports

Conserving

Output

Parameters

References

[1] 2013 ASHRAE Handbook - Fundamentals. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., 2013.

[2] Braun, J. E., S. A. Klein, and J. W. Mitchell. "Effectiveness Models for Cooling Towers and Cooling Coils." ASHRAE Transactions 95, no. 2, (June 1989): 164–174.

[3] Çengel, Yunus A. Heat and Mass Transfer: A Practical Approach. 3rd ed, McGraw-Hill, 2007.

[4] Ding, X., Eppe J.P., Lebrun, J., Wasacz, M. "Cooling Coil Model to be Used in Transient and/or Wet Regimes. Theoretical Analysis and Experimental Validation." Proceedings of the Third International Conference on System Simulation in Buildings (1990): 405-411.

[5] Mitchell, John W., and James E. Braun. Principles of Heating, Ventilation, and Air Conditioning in Buildings. Wiley, 2013.

[6] Shah, R. K., and Dušan P. Sekulić. Fundamentals of Heat Exchanger Design. John Wiley & Sons, 2003.

[7] White, Frank M. Fluid Mechanics. 6th ed, McGraw-Hill, 2009.