Sensorless Six-Step Commutation

Use six-step commutation to run a BLDC motor or PMSM using sensorless control

Since R2025a

Libraries:

Motor Control Blockset /

Controls /

Controllers

Description

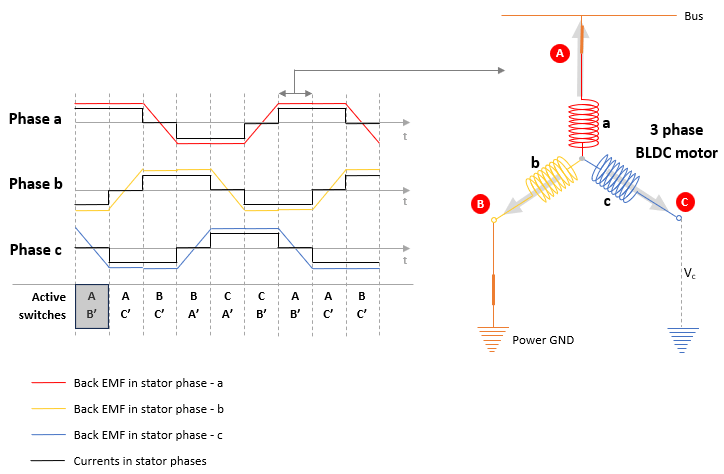

The Sensorless Six-Step Commutation block uses six-step commutation to run a Brushless DC Motor (BLDC) motor or Permanent Magnet Synchronous Motor (PMSM) using sensorless control.

The block uses VabcMeas (measured terminal

voltages) and VdcMeas (DC bus voltage) inputs to

generate duty cycles for the six switches of inverter. You can select the operating mode as

Alignment, Alignment -> Open-loop run, or

Alignment -> Open-loop run -> Controlled commutation.

The Alignment phase in sensorless six-step commutation is used to

initialize the rotor position of a BLDC motor, so that it can start correctly. The method

applies specific voltages to the motor phases A and B, so that the rotor is forced to align

with a known position (-30 electrical degrees with respect to phase A).

The Open-loop run phase in sensorless six-step commutation is used to

reach a speed for the motor to generate sufficient back-EMF that can be used to detect the

zero crossings of back-EMF (the recommended value for this speed can vary from 10 - 30% of

motor rated speed). In this phase, you need to provide the voltage magnitude (Open-loop

duty cycle) and acceleration as inputs. The frequency of applied voltage (or motor speed)

increases linearly according to another set of inputs – ramp-up time and target open loop

speed. Initially, a voltage is applied to all three phases, with a slow increase in

frequency of the applied voltage. The rotor is expected to synchronize with applied

voltage, and it continues to rotate at the specified speed. The block acquires terminal

voltage and detects zero crossings of motor back-EMF. These detections are used to compute

the actual speed of the motor and indicate readiness to move to controlled commutation

state.

In the final phase, Controlled commutation, speed and six-step

commutation instants are accurately determined from back-EMF zero cross detections. The

applied magnetic field leads the rotor by 60-120 degrees (electrical). This behavior is the

same as what can be achieved even when using a hall sensor with six-step commutation. The

block uses the zero-crossing point of the back-EMF in the dormant motor phase during each

60-degree sector to determine the moment of activation of dormant phase. It adds a

30-degree offset to the zero-crossing point to turn ON the dormant phase (and turn OFF one

of the other phases) at correct moment in time.

Note

By default, the block uses the Controlled commutation phase, which

uses default pre-populated values for the various parameters. However, you can follow a

sequential workflow by using the option to select the other two phases in the same

block, which also helps to obtain derived values for all required parameters, specific

to your motor, prior to moving to Controlled commutation phase. For

example, you can follow this sequence:

Select

Alignmentphase and deploy the model to run the motor and obtain derived values related to that phase.Select

Open-loop runphase, use derived values fromAlignmentphase, and deploy the model to run the motor and obtain derived values related toOpen-loop runphase.Select

Controlled Commutationphase, use derived values fromAlignmentandOpen-loop runphases, and deploy the model to run the motor in controlled commutation.

Examples

Ports

Input

Output

Parameters

Extended Capabilities

Version History

Introduced in R2025a