loopview

Graphically analyze MIMO feedback loops

Description

loopview(

plots characteristics of the positive-feedback, multi-input,

multi-output (MIMO) feedback loop with plant G,C)G

and controller C.

Use loopview to analyze the performance of a

tuned control system you obtain using looptune.

Note

If you are tuning a Simulink® model with

looptune through an

slTuner interface, analyze

the performance of your control system using

loopview (Simulink Control Design) for

slTuner (requires Simulink

Control Design™).

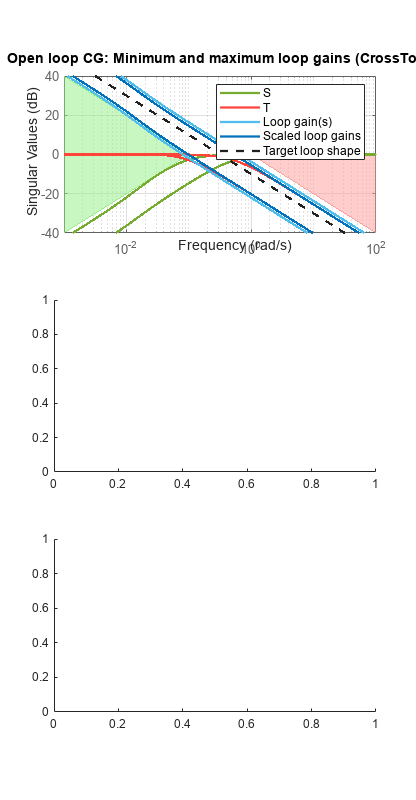

loopview plots the singular values of:

Open-loop frequency responses

G*CandC*GSensitivity function

S = inv(1-G*C)and complementary sensitivityT = 1-SMaximum (target), actual (tuned), and normalized MIMO stability margins.

loopviewplots the multi-loop disk margin (see Stability Analysis Using Disk Margins (Robust Control Toolbox)). Use this plot to verify that the stability margins of the tuned system do not significantly exceed the target value.

For more information about singular values, see sigma.

loopview(

uses the G,C,info)info structure returned by looptune. This

syntax also plots the target and tuned values of tuning constraints

imposed on the system. Additional plots include:

Singular values of the maximum allowed

SandT. The curve markedS/T Maxshows the maximum allowedSon the low-frequency side of the plot, and the maximum allowedTon the high-frequency side. These curves are the constraints thatlooptuneimposes onSandTto enforce the target crossover rangewc.Target and tuned values of constraints imposed by any tuning goal requirements you used with

looptune.

Use loopview with the info

structure to assist in troubleshooting when tuning fails to meet all

requirements.

Examples

Input Arguments

Alternatives

For analyzing Simulink models tuned with looptune through an

slTuner (Simulink Control Design) interface,

use loopview (Simulink Control Design) for

slTuner (requires Simulink

Control Design).

Version History

Introduced in R2011bSee Also

looptune | slTuner (Simulink Control Design) | looptune (for

slTuner) (Simulink Control Design) | loopview (for

slTuner) (Simulink Control Design)