How to Work with ADCs on C2000 MCUs | Getting Started with C2000 Microcontroller Blockset, Part 10

From the series: Getting Started with C2000 Microcontroller Blockset

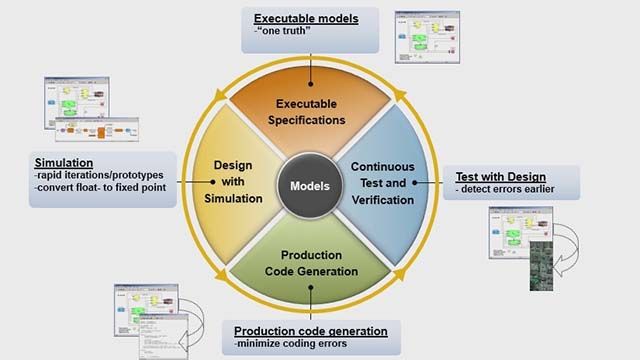

Follow this step-by-step guide video on how to design a model in Simulink® using the analog input ports on a TI C2000™ MCU F28379D LaunchPad™ hardware board using C2000 Microcontoller Blockset. Details on how the ADC module available in C28x C2000 MCUs works are discussed.

Published: 13 Jan 2025