Monitor and Tune GPIOs, ADCs, DACs, and ePWMs on C2000 MCUs | Getting Started with C2000 Microcontroller Blockset, Part 15

From the series: Getting Started with C2000 Microcontroller Blockset

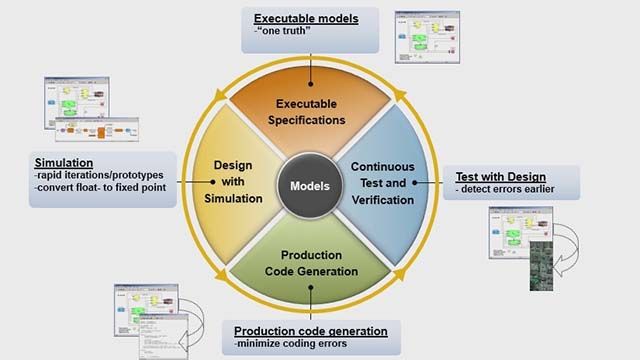

Learn how to use Model-Based Design to work with GPIOs, ADCs, DACs, and ePWMs on TI C2000™ MCUs using C2000 Microcontroller Blockset in Simulink®. Learn how you can use the monitoring and tuning capabilities offered by C2000 Microcontroller Blockset to tune the signals of an embedded algorithm running on a C2000 microcontroller from the Simulink enviroment and also log the signals in a host computer.

Published: 13 Jan 2025