What Is Multivariate Analysis of Variance (MANOVA)?

Multivariate analysis of variance (MANOVA) is a statistical technique used to analyze differences between two or more groups when there are multiple dependent variables. The primary goal of MANOVA is to determine whether the means of the dependent variables differ significantly across groups while considering the interrelationships between the variables.

How Is MANOVA Different from ANOVA?

MANOVA expands upon the concept of analysis of variance (ANOVA) by considering situations where there are multiple response variables. Take a scenario where you are working with data regarding different tire models of an automotive vehicle and aim to understand and analyze the effect of these tires (factors or independent variables) on various performance indicators such as fuel efficiency and tire durability (dependent variables); both ANOVA and MANOVA could be employed to understand the effects of the factors on the response variables.

ANOVA allows you to assess the impact of one or more factors on a single dependent variable at a time. In this case, you could examine how different tire models (the factor) affect fuel efficiency (the dependent variable). On the other hand, with MANOVA, you can simultaneously explore the effects on two or more dependent variables. Here, you could analyze how different tire models (the factor) collectively influence multiple performance indicators such as fuel efficiency and tire durability (the dependent variables).

Why Use MANOVA?

MANOVA allows you to explore whether significant differences exist between groups across a combination of dependent variables. By considering multiple dependent variables simultaneously, MANOVA provides a more comprehensive understanding of group differences and patterns. Conducting separate ANOVAs on multiple dependent variables can increase the chance of false positives (Type I error). MANOVA manages this error rate while analyzing the effect of independent variables on multiple dependent variables simultaneously. MANOVA helps you address questions such as:

- How do different wing configurations in aircraft designs impact factors such as structural strength, weight, and aerodynamic efficiency?

- In semiconductor manufacturing processes, do changes in temperature, pressure, and chemical composition significantly affect outcomes like yield, reliability, and performance?

- Are there notable differences in certain car characteristics—such as fuel efficiency or safety ratings—based on the country of manufacture?

- Do various flower species exhibit statistically significant differences in measurements such as sepal and petal lengths and widths?

Box plot of sepal length grouped by flower species created with the results of a one-way MANOVA in MATLAB.

Assumptions of MANOVA

In general, when conducting a MANOVA test, the following assumptions are made regarding the input data:

- Assumption of Normality: The data within each group follows a normal distribution.

- Assumption of Homogeneity: The variance-covariance matrix of the dependent variables is equal across groups.

- Assumption of Independence: The observations within and between groups are mutually independent.

These assumptions are important to ensure the validity, accuracy, and reliability of the MANOVA analysis and results.

Performing MANOVA Using MATLAB

MATLAB® and Statistics and Machine Learning Toolbox™ provide a range of functionality to understand, visualize, and perform multivariate analysis of variance (MANOVA) on your data. You can:

- Use the

manovafunction to perform one-, two-, or n-way MANOVA. - Understand the statistical significance of the MANOVA results, including model terms, error, F-statistic, and p-value.

- Perform multiple comparisons of marginal means for MANOVA, allowing for pairwise comparisons of group means across multiple dependent variables.

- Perform various tests on the MANOVA results, including linear hypothesis tests and Bartlett’s tests.

- Visualize MANOVA results using various techniques such as box plots, dendrograms, and expected marginal means plots.

Examples and How To

Software Reference

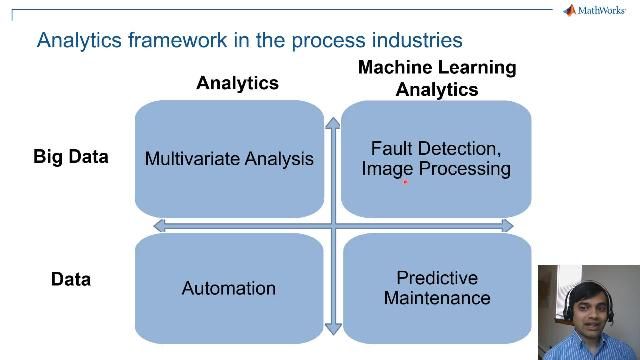

See also: linear model, nonlinear model, nonlinear regression, probability distributions, manufacturing analytics, clustering, process capability